Preparation of an Efficiency and Cost Savings Plan in a Commercial Laboratory

01. Context

A laboratory providing analytical services for the agri-food sectors launched a project aimed at improving process efficiency, reducing production costs, and increasing productivity.

The reasons for launching this project included a significant increase in sample volume, increasingly stringent regulatory requirements regarding quality, and the growing complexity of interactions between the technical department and other departments such as finance, commercial, marketing, etc. In this context of rising demands, where available human and technical resources were limited and investments were quite constrained, the logical solution was to enhance the efficiency of production processes, cut costs, and boost productivity.

Initially, the project was designed and managed internally by the company’s staff. However, after a year, management realized the project was not progressing as expected. The laboratory identified a clear problem of resource constraints, as they had to prioritize daily operations. Another common issue was resistance to change among the staff, coupled with insufficient knowledge and experience in managing such projects among some team members. This led to a lack of sufficient data and, at times, inadequate analysis for an optimal design of the strategic efficiency plan.

02. Challenge

The challenge of the project was clear.

“To design a strategic efficiency improvement plan, tailored to the specific activities of the laboratory and the available resources, that would yield tangible and measurable results in the shortest possible time”.

03. Approach

Initially, the work completed on the project up to that point was analyzed, and subsequently, a structured plan was implemented in three phases over a duration of three months. In the first phase, an analysis of the initial situation was conducted, which involved reviewing the internal context of the company. This included an assessment of the scope of analytical services offered, both accredited and non-accredited, as well as the facilities and equipment, human resources, competencies, qualifications, and organization. A detailed study of the analytical operations and their interrelation and integration with other support activities was included, for which the existing workflow diagrams and indicators were evaluated.

It is important to highlight that this initial evaluation covered not only the analytical phase but also the pre-analytical phase, focusing on sample collection, commercial activities, financial aspects, and client contracts, as well as the post-analytical phase, which includes financial aspects and both technical and management support for the client.

In the second phase, a detailed analysis of the collected data was performed, identifying areas for improvement and bottlenecks.

In the third phase of the project, a strategic plan was developed based on the identified needs, and strategic objectives and their corresponding indicators were defined. Finally, once the strategy and scope of the project were defined, an action plan was prepared. This included defining the necessary human and technical resources, organizing using a RACI matrix, outlining the tasks to be performed, their objectives and milestones, follow-up actions, and deliverables, all integrated into a work schedule.

04. Results

From the analysis of the project’s progress, the following issues were identified:

- The project suffered from a lack of team organization.

- It operated in bursts based on the laboratory’s workload and available time.

- The analysis of production processes and the indicators used were not detailed enough to detect deficiencies and areas for improvement.

- The perspective was very insular and lacked an external, critical, and independent viewpoint.

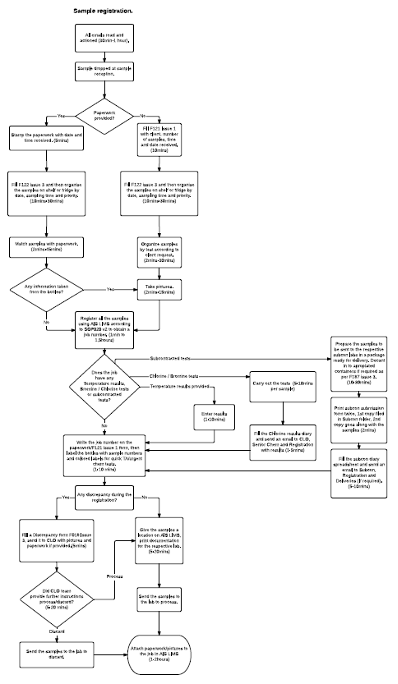

In light of this initial analysis of the situation, existing workflows were detailed, and additional new indicators were implemented to provide valuable data on the current situation. Figure 1 shows the flow diagram corresponding to sample reception.

The main areas for improvement identified were:

- Sample collection process and its reception in the laboratory: Although the LIMS used had a module for sample collection management, it did not integrate this process well, and its capabilities were limited. There was no complete traceability of the samples, nor did it assist in the logistics of sample collection. Sample reception was a clear bottleneck, as many of the received samples were unscheduled. With a low level of digitalization, registering the samples in the LIMS often required contacting the client to collect necessary information.

- Workflow inefficiencies: Sometimes workflows contained illogical actions and had room for improvement, such as unnecessary movements and prolonged waiting times. The search for samples shared by several departments was identified as a significant area for improvement.

- Low automation and digitalization: While there were autosamplers for analytical equipment for parameters such as metals or organic compounds, the generation of results was not integrated with the LIMS, and many processes were manual.

- Lack of a client portal: There was no client portal for direct contracting or downloading reports or raw data.

- Complex procurement process: Although integrated with the finance department, procurement was a complex process that consumed time from the personnel designated for analyses.

With the identification of these areas for improvement, a strategic plan was prepared where the proposed improvement actions were prioritized based on the necessary resources, estimated implementation time, and expected benefits. In collaboration with the company, a phased action plan was defined, spanning three years, during which 15 of the identified actions would be implemented.

As a result, the management of this project allowed the company to:

- Develop a strategic efficiency plan in just three months.

- Reduce the internal resources needed to prepare this plan.

- Enrich the plan with expert, external, and independent insight.